JPP-Ⅱ(JUZEN PHARMACEUTICAL PLANT-Ⅱ) Multi-purpose plant in compliance with GMP

JPP-Ⅱ is a multi-purpose API plant which was altered from the conventional plant for production of intermediates, following the same concept adopted in the construction of JPP-Ⅰ.

UP to now, we have received substantial number of inspections by domestic/abroad major pharmaceutical companies and by FDA,

as well, in 2005, 2009, 2016, 2018, 2019 obtaining high evaluations at such occasions.

Features of JPP-Ⅱ

-

The building is steel framed and 6 stories high with 2,740m2 of total floor area.

Same as for JPP-Ⅰ, ALC is employed for outside wall, with which the building provides airtight structure in combination with no-window system to realize certain measures for control of vermin and dust. - Two clean rooms (class 100,000) with HEPA filters are provided (acid proof and alkali proof), where all of the processes after crystallization on are carried out.

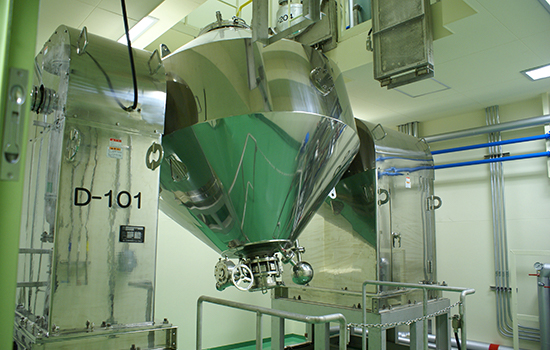

- In the synthetic zone, such cross contamination prevention measures are taken as installing charge-in booths and segregating centrifuge rooms and drying rooms from other zone, as well.

- With the substantial equipment which can respond to wide range of reaction conditions, this plant is suitably adoptable for not only commercial production but also manufacturing some tens kg or more of APIs for investigational drug.

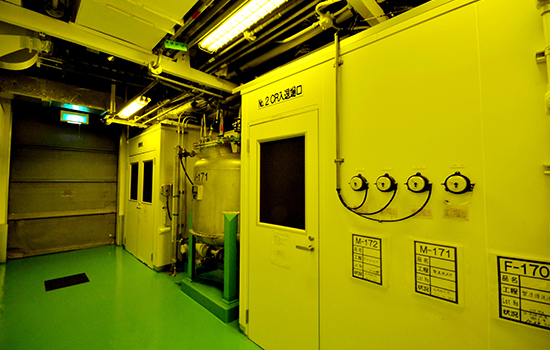

Clean room

Two clean rooms (class 100,000), responding to acid/alkali products, can be utilized for the processes after crystallization on for the final product.

Synthesizing equipment

Substantial utility equipment allows us to cope with wide range of reactions.

-20℃ to 300℃ of cooling/heating media are available from the chiller unit along with heating media equipment.

Facility and equipment in the plant(JPP-Ⅱ) in compliance with GMP

| Description of equipment | Specification | numbers |

|---|---|---|

| Reaction vessel | GL 0.7M3 -12M3 |

18 |

| Reaction vessel | SUS 0.7M3 -12M3 |

10 |

| Centrifuge | ETFE 48B |

4 |

| Filter dryer | SUS 2.5M2 |

1 |

| Vacuum vibration dryer | Hastelloy C 1.6M3 |

1 |

| Vacuum vibration dryer | SUS 1.6M3 |

1 |

| Conical dryer | GL 0.5M3 -3M3 |

3 |

| Nauter dryer | SUS 2M3 |

1 |

| Vacuum shelf dryer | SUS 10L × 56 plates / dryer |

1 |

| Clean room | class 100,000 | 2 |

| Grinding equipment | Hammer Mill(Sample Mill), Feather Mill(Pharma Mill, Power Mill) | |

| Incidental equipment | Purified water generator(UFW), High vacuum distillation equipment (down to 10Pa) | |

| Utility | Steam, Heating media, Cold water, -20℃ of brine(-10℃~250℃ reaction achievable) | |