JPP-Ⅰ(JUZEN PHARMACEUTICAL PLANT-Ⅰ) Multi-purpose plant in compliance with GMP

JPP-Ⅰ, completed in July of 1998, is a multi-purpose plant dedicated to API in compliance with GMP.

This Plant received GMP Inspections (PAI) of FDA on API for new drugs to be marketed in trilateral countries of Japan, USA and EU, in 2000, 2005, 2009, 2012, 2016, 2018, 2019 when evaluated as extremely high level of GMP control by FDA.

Feature of JPP-Ⅰ

-

The building is steel framed and 6 stories high with 4,320m2 of total floor area.

On the 1st & 2nd floor are provided 4 clean rooms (class 100,000) with HEPA filter and utility equipment, and the floors of 3rd or higher are designed as synthesizing zone with various kinds of equipment. - ALC (Air- foamed Light Concrete) is employed for outside wall, with which the building provides high airtight structure in combination with no-window system to realize certain measures for control of vermin and dust.

- Design for the inside of the plant assures perfect cross contamination prevention with careful equipment configuration by adopting rational flow diagram, and air flow control system, as well.

Clean room

The processes from crystallization and on, particularly important in GMP, are carried out in clean room. Especially, installation of the large-sized filter dryer in the clean room enables Juzen to respond effectively to the GMP requirement regarding handling of powder bulk materials

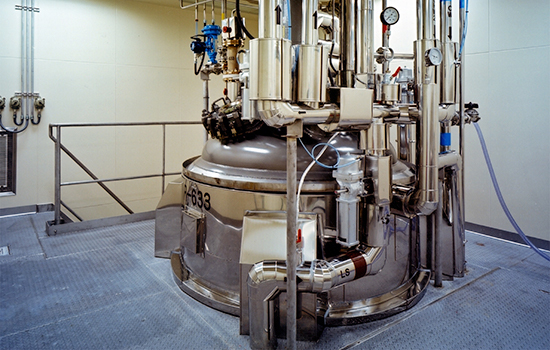

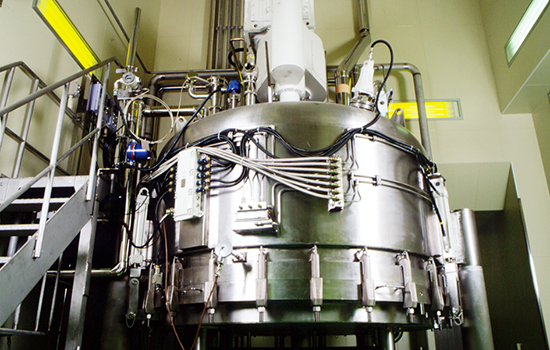

Synthesizing equipment

In the design of JPP-Ⅰ, careful plan and consideration have been given to the most important "washing and cleaning"process in GMP so that any kinds of contamination can be removed.

Facility and equipment in the plant(JPP-Ⅰ) in compliance with GMP

| Description of equipment | Specification | numbers |

|---|---|---|

| Reaction vessel | GL 1M3 -12M3 |

10 |

| Reaction vessel | SUS 0.5M3 -12M3 |

17 |

| Autoclave | SUS 5M3 |

2 |

| Low temp reaction vessel | SUS 5M3 |

1 |

| Centrifuge | SUS, Hastelloy C 55B |

2 |

| Filter dryer | SUS, Hastelloy C 1.5M2 - 4M2 |

6 |

| Vacuum shelf dryer | SUS 29L X 30 plates / dryer |

3 |

| Conical dryer | SUS,GL 1M3 |

3 |

| Freeze dryer | SUS | 2 |

| Vacuum vibration dryer | SUS 0.6M3 |

1 |

| Clean room | class 100,000 | 4 |

| Grinding equipment | Jet Mill(Spiral), Hammer Mill(Atomizer,Pulverizer), Pin Mill(Kolloplex) | |

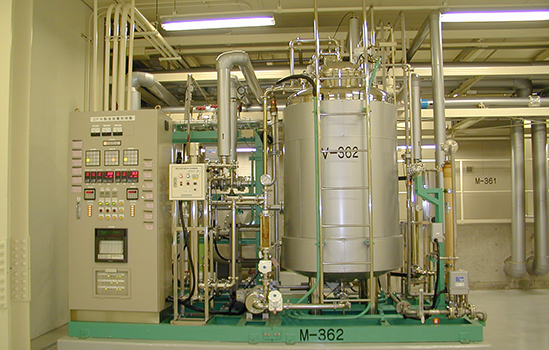

| Incidental equipment | Purified water generator(UFW), Nitrogen gas generator(PSA type) | |

| Ultra-low temp facility | Cooling medium(Min -100℃) | |

| Utility | steam, cold water, -40℃ of brine(-30℃ - 140℃ reaction achievable) | |